Dosing Tank

We offer a full chemical dosing tank range with each dosing tank blow moulded in virgin MDPE to food grade standards, with the manufacturing taking place right here in the U.K.

Designed specifically for use in the water treatment, effluent treatment and process control sectors - the chemically resistant MDPE tanks can be manufactured in UV stabilised black for use with chemicals with a low vapour pressure, allowing us to supply dosing tanks suitable for Sodium Hypochlorite and dosing tanks suitable for Hydrogen Peroxide.

Alternatively we manufacture our dosing tank range in natural MDPE for use with chemicals where UV stabilisation isn't an issue or where the tanks aren't subjected to UV radiation.

Dosing Tank Mounted Equipment

Our cylindrical dosing tanks include a flat raised section shelf section which can be used to mount equipment on top of the tank. This is ideal for mounting items such as dosing pumps, industrial mixers, and instrumentation. Where required we can fit the dosing tank with a strengthening plate when a combination of equipment is used or where weight is a concern.

Dosing Tank With Screw Fitting Lid and Graduated Scale

In addition to the elevated flat mounting section - the dosing tank has a black screw fitting lid which can be tightening down on top of the tank.

The male threaded fitting that the lid screws down onto is moulded into the MDPE allowing the lid to create a tight seal with the dosing tank.

Also when manufacturing the tank a raised graduated scale is incorporated into the design of the tank and coloured black. With the natural MDPE dosing tanks this allows the MDPE dosing tanks to allow a quick visual indication to check the level of reagent located within the tank.

Dosing Tanks for process applications

Each of our dosing tanks can be supplied ready for use in process applications. We can fit all manner of equipment to the tanks either for stand alone applications - such as industrial mixers for keeping lime solutions in suspension for pH neutralisation, or we can ensure that the tanks are suitable for integration into a larger process, by adding liquid level electrodes, dosing pumps and supply the dosing tanks complete with pipework, flanges, and valves to integrate into an existing process or new process.

Dosing Tank Range

DT25

The DT25 is a 25 Litre Dosing Tank manufactured in chemically resistant MDPE and available in either black for UV stabilisation or natural MDPE.

Manufactured with a front mounted graduated scale for easy visual identification of liquid level and black screw top cap for securing liquid contents.

The DT25 has a capacity of 25 litres and is rectangular in shape with dimensions 250 W x 350 H x 340 D (mm).

DT50

The DT50 is a 50 Litre Dosing Tank manufactured in chemically resistant MDPE and available in either black for UV stabilisation or natural MDPE.

Manufactured with a front mounted graduated scale for easy visual identification of liquid level and black screw top cap for securing liquid contents.

The DT50 has a capacity of 50 litres and is cylindrical in shape with dimensions of 425 Dia x 500 H (mm).

The DT50 has a flat raised section for the mounting of equipment.

DT100

The DT100 is a 100 Litre Dosing Tank manufactured in chemically resistant MDPE and available in either black for UV stabilisation or natural MDPE.

Manufactured with a front mounted graduated scale for easy visual identification of liquid level and black screw top cap for securing liquid contents.

The DT100 has a capacity of 100 litres and is cylindrical in shape with dimensions of 495 Dia x 700 H (mm).

The DT100 has a flat raised section for the mounting of equipment.

DT200

The DT200 is a 200 Litre Dosing Tank manufactured in chemically resistant MDPE and available in either black for UV stabilisation or natural MDPE.

Manufactured with a front mounted graduated scale for easy visual identification of liquid level and black screw top cap for securing liquid contents.

The DT200 has a capacity of 200 litres and is cylindrical in shape with dimensions of 635 Dia x 765 H (mm).

The DT200 has a flat raised section for the mounting of equipment.

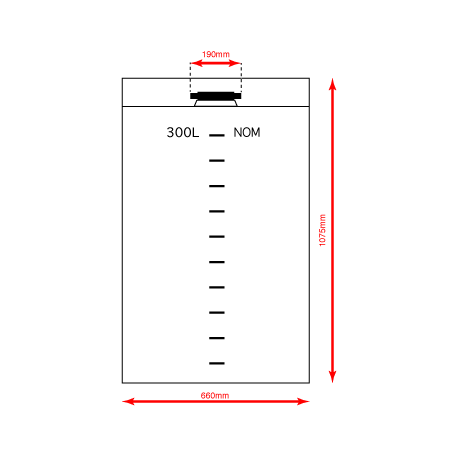

DT300

The DT300 is a 300 Litre Dosing Tank manufactured in chemically resistant MDPE and available in either black for UV stabilisation or natural MDPE.

Manufactured with a front mounted graduated scale for easy visual identification of liquid level and black screw top cap for securing liquid contents.

The DT300 has a capacity of 300 litres and is cylindrical in shape with dimensions of 660 Dia x 1075 H (mm).

The DT300 has a flat raised section for the mounting of equipment.

DT500

The DT500 is a 500 Litre Dosing Tank manufactured in chemically resistant MDPE and available in either black for UV stabilisation or natural MDPE.

Manufactured with a front mounted graduated scale for easy visual identification of liquid level and black screw top cap for securing liquid contents.

The DT500 has a capacity of 500 litres and is cylindrical in shape with dimensions of 815 Dia x 1100 H (mm).

The DT500 has a flat raised section for the mounting of equipment and a large opening measuring 270mm in diameter.

DT1000

The DT1000 is a 1000 Litre Dosing Tank manufactured in chemically resistant MDPE and available in either black for UV stabilisation or natural MDPE.

Manufactured with a front mounted graduated scale for easy visual identification of liquid level and black screw top cap for securing liquid contents.

The DT1000 has a capacity of 1000 litres and is cylindrical in shape with dimensions of 1065 Dia x 1355 H (mm).

The DT1000 has a flat raised section for the mounting of equipment and a large opening measuring 270mm in diameter.