11243-PVDF

Multi-Function Valve for Dosing Pumps

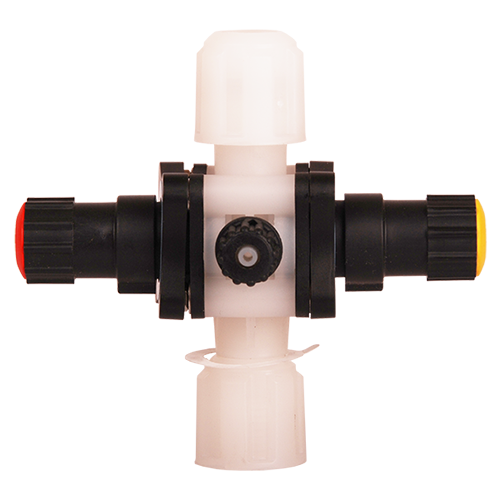

The 11243-PVDF multi-function valve is designed to be mounted on top of a dosing pump to provide anti-syphon and loading valve functionality combined with pressure relief or safety valve functionality.

11243-PVDF Multi-Function Valve Introduction

The 11243-PVDF multi-function valve combines loading valve and pressure relief functionality into the same dosing pump mounted housing.

Designed with functionality in mind - the 11243-PVDF replaces the locking nut on the discharge side of the dosing pump and terminates in a hose fixing kit for either 4x6mm or 8x12mm dosing tube.

The 11243-PVDF has two adjustable dials mounted on either side of the main body which allow the user to adjust the following:-

- The loading valve pressure that the dosing pump must work against.

- The pressure relief or safety valve set-point.

Simple to install and use the multi-function valve is manufactured in chemically resistant PVDF with dual PTFE diaphragms and a choice of seal and O-ring materials.

Safety / Pressure Relief

The safety valve can be set from 0 - 18 Bar by simply pulling out the knob, twisting into position, and pushing back into place.

Loading / Anti-Syphon

The loading valve can be set from 0 - 5 Bar by pulling out the knob, twisting into position, and pushing back into place.

Anti-Syphon / Loading Valve

The 11243-PVDF has a loading valve / anti-syphon valve functionality. This is manually adjustable between 0 - 5 Bar and results in the pressure being applied by an internal PTFE diaphragm.

The benefits of using a diaphragm to restrict the flow results in a constant and repeatable back pressure for the pump to work against. This ensures that the amount of chemical delivered with each pulse remaining consistent for precision chemical dosing.

In addition to ensuring that the amount of chemical can be accurately calculated, it resists the effects of syphoning when installation types are at risk of the syphoning effect.

Safety Valve / Pressure Relief

The safety valve / pressure relief functionality can be adjusted using the secondary dial of the multi-function valve. This results in a second PTFE diaphragm being positioned to perform the pressure relief functionality.

The set-point for the pressure relief can be set between 0 - 18 Bar and should the pressure in the discharge pipework exceed the set value, the discharge media is diverted through the front pressure relief connection using the supplied 4 x 6mm discharge tube.

Wetted Parts

The 11243-PVDF is available with a combination of wetted parts and to suit either the 4x6mm tubing of the AT1, AT2, and AT3 dosing pumps or to suit the 8x12mm tubing on the AT4 series of dosing pumps.

| Part Number | Body Material | Diaphragm Material | Seal Material | Connections |

|---|---|---|---|---|

| 11243-PVDF | PVDF | PTFE | Viton / EPDM | 4x6mm |

| 11243-PVDFGP | PVDF | PTFE | Viton / EPDM | 8x12mm |

The seal material is available in either EPDM or Viton (© DuPont / Chemours) and we recommend checking our chemical compatibility database and your chemical supplier, to ensure that all the parts of the liquid end are compatible with the chemical to be dosed.

11243 Features & Benefits

The 11243 multi-function valves are designed to be simply integrated onto new or existing dosing pumps to provide a loading valve / anti-syphon valve and a pressure relief / safety valve functionality.

Combining 2 separate tension adjustable PTFE diaphragms the valves can be easily setup to provide manually adjustable loading from a pressure of 0 - 5 Bar and a manually adjustable pressure relief from 0 - 18 Bar.

The multi-function can be simply fitted to a dosing pump by removing the top lock nut and tightening the multi-function valve in its place. The discharge tubing is connected to the outlet of the multi-function valve as normal.

The design of the PTFE diaphragms ensures that they maintain the set values even during constant operation providing constant chemical dosing against the fixed pressure.

The pressure relief valve provides safety functionality opening a valve should the pressure of the discharge line exceed the set-point on the multifunction valve.

Manufactured in chemically resistant PVDF with a choice of seal materials - the 11243 multi-function valve is of proven design for a long operational lifespan when paired with compatible chemical reagents.

10400 Specifications

-

Specifications

Mult-function Valve with Pressure Relief and Anti-Syphon

Model Number:- 11243

Body Material:- PVDF

Pressure Relief Diaphragm Material:- PTFE

Operating Range:-0 - 18 Bar

Loading Valve Diaphragm Material:-PTFE

Operating Range:-0 - 5 Bar

Connections:- 4x6mm & 8x12mm

Mounting Type:- Dosing Pump Mounted

-

Applications

The 11243-PVDF is a multi-function valve designed for mounting directly on top of dosing pumps.

Providing dosing pumps with a loading valve to ensure that they work against a fixed pressure, ensuring that the output from each pump stroke is precise even when working at against variable pressure in pipework. The anti-syphon functionality prevents the chemical reagent syphoning through the pump in installation types that are risk from syphoning.

The pressure relief / safety valve prevents a dosing pump from pumping against a blocked line, or where the pressure exceeds the safe rating of the pipework. The conveniently located bleed valve on the front of the 11243 multi-function valve ensures that the chemical reagent can be safely returned back to origin.

The dual PTFE diaphragms are spring compressed and fully user adjustable - ensuring that the pressure rating remains constant even in vibrating or oscillating environments and are ideal for pairing with dosing pumps.

Manufactured in chemically resistant PVDF with a PTFE diaphragm and a choice of seal materials the 11243 is designed to be compatible with a wide range of chemical reagents.

-

Ordering Information

Model Number Body Material Diaphragm Seals & O-Rings Tubing Connection 11243-PVDF PVDF PTFE Viton 4x6mm 11243LP-PVDF PVDF PTFE EPDM 8x12mm 11243GP PVDF PTFE Viton 4x6mm 11243 PVDF PTFE EPDM 8x12mm Please use our chemical compatibility checker to ensure that the wetted parts are compatible with your process. If you're unsure please don't hesitate to contact our friendly sales team.